how prusa is using the world’s largest 3D-printing farm to produce medical gear

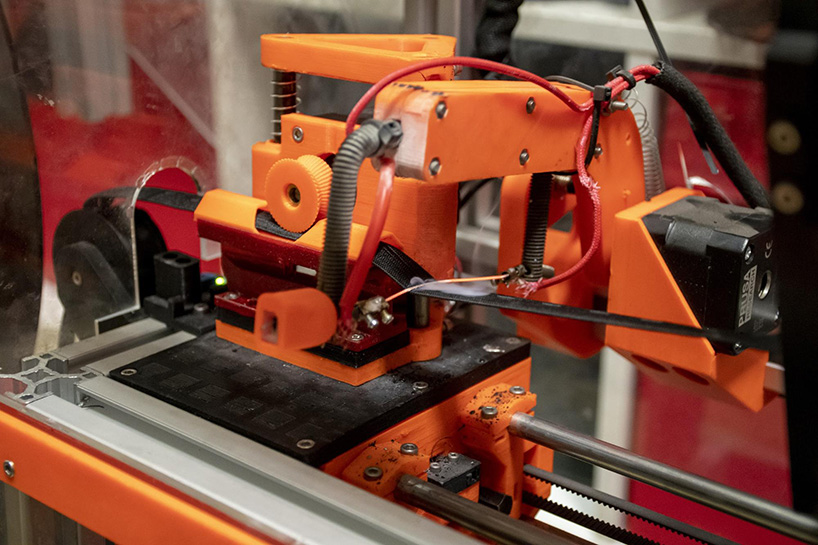

as the pandemic COVID-19 takes over the whole world, the 3D-printing community is responding. earlier this week, we saw how italian engineers and fabricators have volunteered to rapidly 3D-print respirator valves. today, josef průša — founder of prusa research, the world’s largest 3D printing farm — has spoken saying that they are also looking for ways to help and most importantly, what he has learned about where 3D printing doesn’t work.

all images courtesy of prusa printers

‘I don’t intend to hamper the vibe we have now – not by a long shot, but printing respirators might not be the best idea at this time,’ comments josef průša on the blog post. he says that none of the designs available right now have been tested to secure they provide the protection needed. ‘to help with this, we have collected as many designs as we could find, and are working with experts to see if we can verify which ones really work.’ he continues. ‘what are the key focus points? first, it’s the sealing, then the filter itself, the filter to the mask, and how the mask attaches to the face – it all must be perfect.’ he also questions the porosity of the printed parts and the safety concerns that come from that. ‘I understand you’re trying to help, but PLEASE spread this info into your 3D printing groups.’

průša says that even though 3D-printed respirators need a closer look, that doesn’t mean he won’t be putting his 3D-printing farms to good use. his research has been directed towards protective gear for medical professionals which they can produce safely. this news comes in very handy, as countries like italy have been seeing how the novel coronavirus is taking a death toll among its doctors, dying at a rate of more than one per day because of the lack of protective gear.

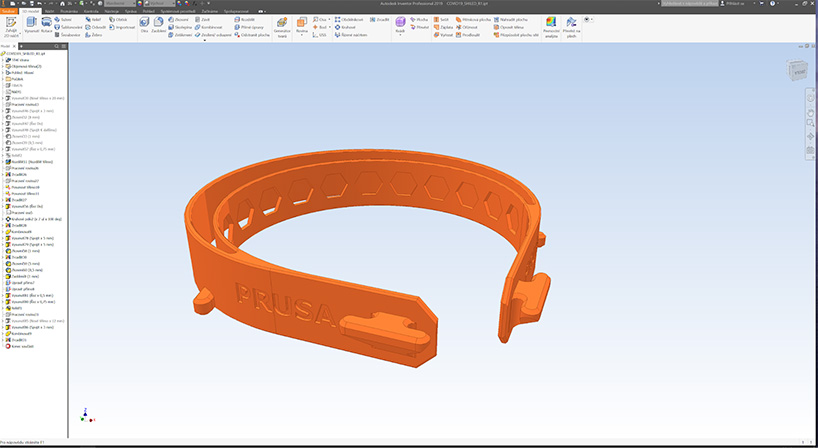

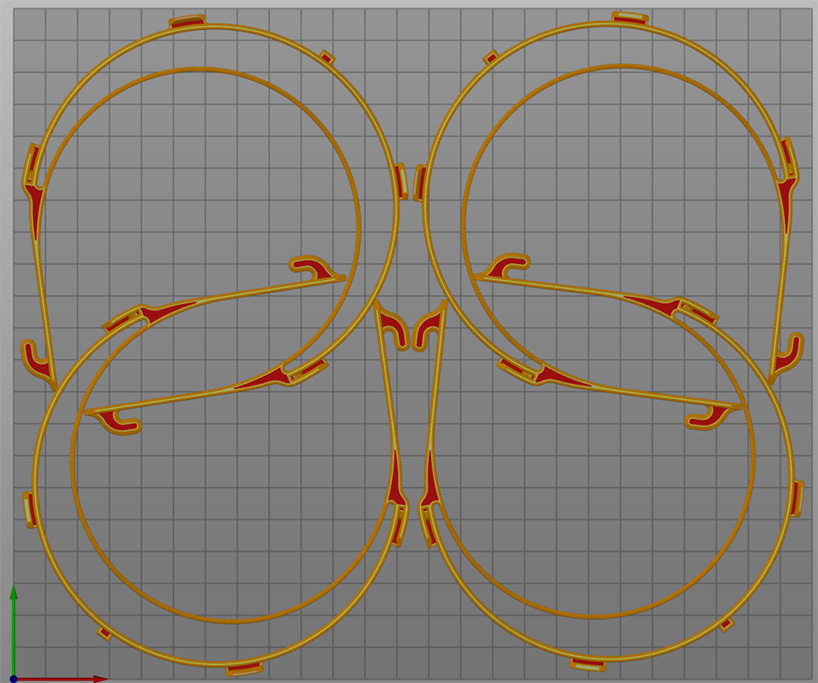

‘we were notified on facebook that doctors are in great need of face shields and that there is already a great face shield design available online,’ the blog post continues. ‘we took it as a starting point and decided that we would adjust it for easier and faster 3D printing – e.g. there shouldn’t be any supports required and we should fit as many of them onto a single print sheet as possible. so we started working on it immediately. after all, it is very important to keep the guys, who will take care of us in the darkest times, as healthy as possible. these shields will help protect their eyes and face from coughing and sneezing of their patients.’

průša goes on to announce that they have started the prototype production and that the first unit went to a hospital for field testing and verification. once verified, the will move on to design protective goggles. currently, the farm is able to produce 800 pieces a day but he says that theoretically it could go to up to 4,000 pieces a day. the design can be printed relatively safe by individuals in lower numbers to help local communities too.

‘I want to get this to as many people who need it as soon as possible, around the world,’ průša concludes.’if you guys have the tools and capacity for it, you can start preparing now, even before we have the final design. it’s a great time to give your printer a tuneup and to stock up on materials so you are ready to start printing as soon as we release the designs.’

juliana neira I designboom

mar 20, 2020